The Ultimate Guide To Aluminum Castings Company

Table of Contents9 Simple Techniques For Aluminum Castings Company3 Simple Techniques For Aluminum Castings CompanySome Known Details About Aluminum Castings Company Everything about Aluminum Castings CompanyAbout Aluminum Castings CompanyNot known Details About Aluminum Castings Company Everything about Aluminum Castings Company

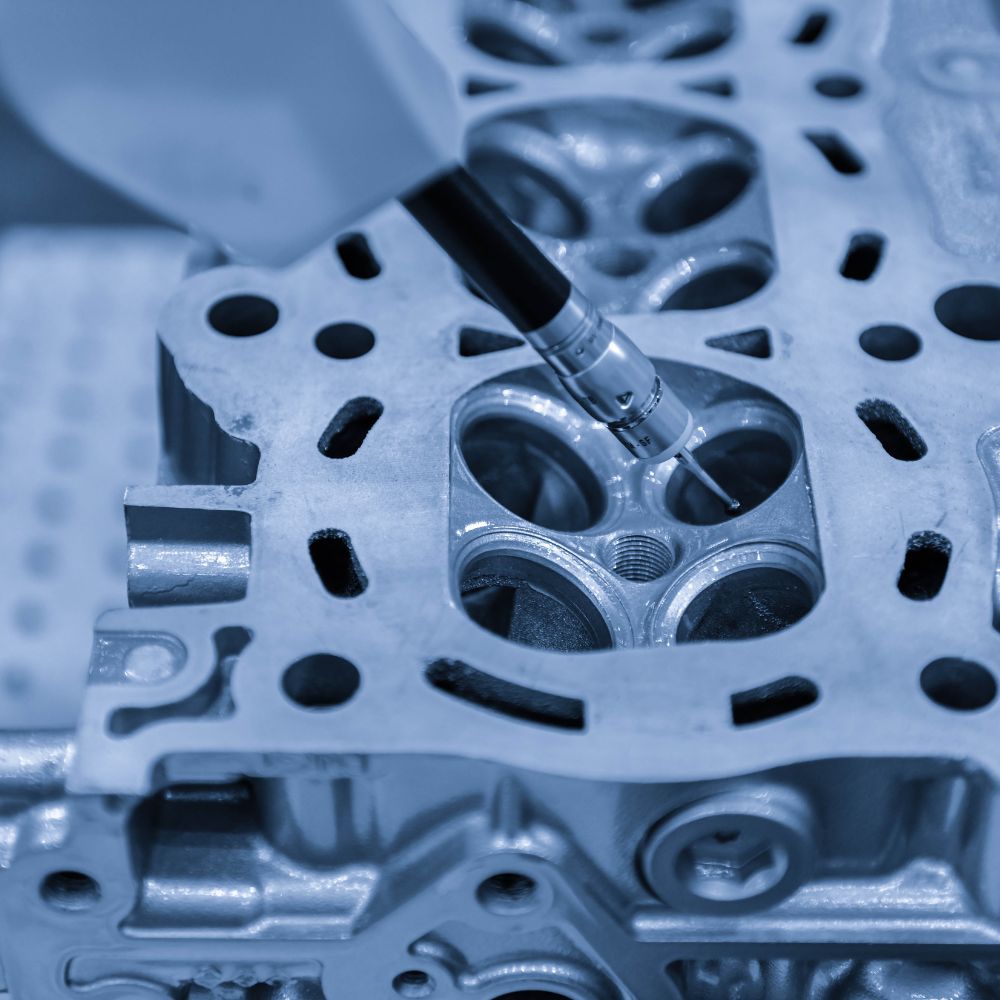

Then machined to tolerances with an additional operation like thread cutting and dealing with. Steel casting like injection molding utilizes a sprue and entrance system for mold and mildew circulation however can accommodate a much higher variant in wall density. Ceramic shell investment process requires no draft angles as the component is burst out of the ceramic as a one-off waste mold.If threads always need to be machined after casting this is going to be a little bit above spending plan. I listen to some factories can work with close tolerances as much as regarding +/ -0.010 in/in.

Not known Details About Aluminum Castings Company

Most light weight aluminum creators will place on a big track and dance number regarding helping you select from the thousands of alloys that are readily available. They will certainly then scientifically get to the very best alloy and mood option for your certain application. It constantly turns out to be 356-T6.;--RRB-;-- Lost foam is particularly proficient at difficult parts, where it would certainly be impossible to remove the pattern from the mold and mildew.

We just have the 2 places and the business specializes in Light weight aluminum Pass away Casting. The business that utilized to own the United States procedure is no much longer, and was gotten by the Italian business a little over a year ago.

Considering that this is such a tiny business, and has yet to tidy up the mess from the prior proprietor, I am liable for 45 staff members and 38 equipments on my 2 shifts (Second and Third Changes). Being accountable for so much was not something I had actually anticipated, yet I have actually made it my interest to produce a smooth operation for my firm.

We have numerous acquired problems, the greatest of which is our Great deal Traceability ... and this is where I need every one of the assistance and recommendations I can get. The system embeded in area is utilized to trace the top quality of 35 different items for numerous vehicle companies. Concerning half of our items are casted in-house and machined in my side of the plant.

The 3-Minute Rule for Aluminum Castings Company

We have many concerns in our casting department, and its frequently enhancing - Sand Mold. https://anotepad.com/notes/3yh7dkpc. The light weight aluminum blocks offer extremely couple of problems and are less complicated to manage, but we still have our issues from time to time. Our lot tracing methods seem very primitive, an actual tag (printed sheet of paper) that physically follows the components

We have actually won 14 brand-new contracts in the last 4 months, and brand-new production is starting within a year. We need to be able to tighten it down to the shift at a minimum. Preferably the time, driver, machine, component #, batch #, amount.

Getting My Aluminum Castings Company To Work

The same system needs to be made use of for all phases of production: Spreading, Trimming, Shot Blasting, Machining, et all. I am an absolute amateur with this side of business, and have actually always stayed focused on keeping CNC machines, writing programs and leading jobs. Any and all help would certainly be significantly valued.

I'm not certain if I posted this in the ideal section of the forums. Core Making. If I incorrectly posted this below, go to the website please forgive me

It's definitely a subject I have actually thought about at length and have had the benefit of having pals that were expert foundrymen and capability to observe their methods. There absolutely is no factor that industry finest practice can not be accomplished by a hobbysist, but whether that is practical or not because setup may be an additional issue.

5 Simple Techniques For Aluminum Castings Company

After that there are typically production tasting prepares to guarantee that everything stays in control along the road. Most shops will certainly have the methods of screening metal examples directly for H2 web content which would be done before any type of mechanical screening. There still is worth to going to the effort of tensile testing or polishing and sectioning if absolutely nothing a lot more as a way of validating you can regulate the uniformity of your mold media, heater song, and as far as making use of scrap steel, I 'd claim neglect that unless you have an extremely reliable resource of information as to the don't presume all wheels are 356, because that is not constantly so.

The 25-Second Trick For Aluminum Castings Company

You need to do the estimation however you will certainly be stunned at that mass of water. Commercial foundries will purge and bury the thaw in a holding heater just to stop H2 infiltration when there is no flow! I utilize a repellent electrical furnace due to the fact that it has no air flow. For factors I'm not quite certain, it seems to have less than climatic degrees of O2, since if I thaw scrap and raise the cover, it will commonly flash when exposed to air.